Construction Take-Off Services A Comprehensive Guide

Construction take off services – Construction take-off services are crucial for accurate project estimations. They involve meticulously analyzing blueprints, specifications, and site surveys to determine material quantities and costs. This process, whether manual or automated, impacts everything from project budgeting to scheduling, ultimately influencing profitability and risk mitigation. From residential to industrial projects, understanding the nuances of these services is key to success.

This guide delves into the various aspects of construction take-off services, covering definitions, processes, benefits, challenges, and technological advancements. We’ll examine how these services are implemented across different construction sectors, providing illustrative examples and case studies to solidify your understanding. Ultimately, we aim to equip you with the knowledge needed to navigate the complexities of construction take-off.

Defining Construction Take-Off Services

Source: biddingestimate.com

Construction take-off services are a crucial first step in any construction project. They involve meticulously determining the quantities of materials needed for a project, essentially providing a detailed bill of quantities. This process is fundamental for accurate budgeting, scheduling, and ultimately, project success. It forms the basis for all subsequent project phases.

These services are essential to avoid costly mistakes later in the project. A precise take-off ensures you have the right amount of materials, minimizing waste and overspending. Accurate calculations are critical for accurate cost estimations, and a well-defined take-off is the foundation for a project’s success.

Types of Take-Off Services

Construction take-off services encompass various approaches, each with its own set of advantages and disadvantages. These methods range from traditional manual methods to advanced automated systems.

- Manual take-off services rely on human interpretation of drawings and specifications. This method typically involves using rulers, calculators, and spreadsheets to calculate material quantities. While often less expensive for smaller projects, it’s prone to human error and can be time-consuming, particularly for complex projects.

- Automated take-off services leverage software applications to process and analyze project drawings and specifications. This automated approach often involves image recognition, data extraction, and calculation to produce a detailed take-off report. This method offers increased accuracy, reduced errors, and faster processing times, especially for large-scale projects. This is often a more expensive approach for small projects, but the advantages in terms of speed and accuracy can make it worthwhile for complex or large-scale projects.

Methodologies in Take-Off Processes

The methodologies employed in take-off processes depend on the project’s scale, complexity, and the type of services utilized. They generally involve quantifying various elements.

- Volume calculations are a critical aspect of the take-off process. For example, determining the cubic footage of concrete for a foundation or the square footage of drywall for walls requires precise calculations based on the provided dimensions. These calculations can be done manually or automatically, depending on the chosen take-off method.

- Material estimations involve determining the exact quantities of various materials needed for the project. This process involves considering factors like material specifications, waste allowances, and project requirements. Accurate material estimations ensure sufficient material availability throughout the project’s lifecycle. For example, an estimation for roofing shingles needs to account for potential overlaps and waste during installation.

Manual vs. Automated Take-Off Comparison

A comparison table showcasing the advantages and disadvantages of manual and automated take-off methods is presented below.

| Method | Advantages | Disadvantages |

|---|---|---|

| Manual Take-Off | Generally lower upfront cost, potentially suitable for smaller projects. Can be adapted to specific needs. | Prone to human error, time-consuming, less accurate for complex projects, and difficult to scale. |

| Automated Take-Off | Higher accuracy, faster processing, scalable to large projects, reduces human error, and can be customized to project specifications. | Higher initial cost, requires software proficiency, may not be suitable for all project types, and can be difficult to adapt to highly unusual specifications. |

Key Components of a Take-Off Service

A construction take-off service is more than just eyeballing a blueprint. It’s a meticulous process requiring precise measurements, accurate calculations, and a solid understanding of the project’s specifications. A good take-off service is the foundation for accurate cost estimations and ultimately, project success.

Essential Elements for a Robust Take-Off Service

A robust take-off service needs a strong foundation of key elements. These elements ensure accuracy and efficiency, ultimately impacting the project’s bottom line. Accuracy is paramount; a small error in measurements can snowball into substantial cost overruns.

- Precise Measurement Techniques: Accurate measurements are the cornerstone of a successful take-off. Using appropriate tools (e.g., laser levels, tape measures) and employing consistent methodologies (e.g., established surveying protocols) are crucial. This minimizes discrepancies and ensures the figures are as close to reality as possible.

- Thorough Data Collection: Data collection is not just about gathering information; it’s about meticulously documenting all necessary details from the project’s blueprints, specifications, and site surveys. A complete data set ensures nothing is missed, allowing for a comprehensive take-off.

- Expert Knowledge and Proficiency: Take-off personnel need a strong understanding of building materials, construction methods, and industry standards. This knowledge is vital for correctly interpreting blueprints and specifications, ensuring that the material quantities are accurately calculated.

- Effective Communication and Collaboration: Clear communication between the take-off team and other project stakeholders (architects, engineers, clients) is essential. Effective communication ensures that everyone is on the same page, avoiding misunderstandings and costly revisions.

Importance of Accuracy and Precision in Take-Off Processes

Accuracy and precision in take-off processes are not merely desirable; they are essential for project success. Inaccurate take-offs can lead to significant cost overruns and delays. A detailed take-off process ensures accurate cost estimates, leading to better budget management and informed decision-making throughout the project lifecycle.

- Reduced Cost Overruns: Accurate take-offs translate to precise cost estimates, minimizing the risk of unexpected expenses. This reduces project risks and allows for more realistic financial planning.

- Improved Project Scheduling: Knowing the exact quantities of materials allows for better scheduling of deliveries and installation. This minimizes delays and ensures the project stays on track.

- Enhanced Profitability: Accurate take-offs directly contribute to a more profitable project. By avoiding cost overruns, projects can generate higher returns and achieve better margins.

Role of Data Collection in Take-Off Services

Data collection is the bedrock of any reliable take-off service. It’s the foundation upon which all calculations are built. The accuracy of the take-off depends entirely on the thoroughness and reliability of the data collected.

| Data Source | Description |

|---|---|

| Blueprints | Detailed architectural and engineering drawings that provide information on building dimensions, layout, and material specifications. |

| Specifications | Detailed documents that specify the materials, finishes, and quantities required for each component of the project. |

| Site Surveys | Measurements and observations taken at the construction site, providing information on existing conditions and site-specific factors. These often include topographical data. |

| Material Price Lists | Current market prices for various construction materials. These lists are crucial for accurate cost estimations. |

Take-Off Service Processes and Procedures

Construction take-off services are crucial for accurate cost estimations. These services involve meticulously documenting materials and labor needed for a project. Proper procedures and meticulous measurements are essential to avoid costly errors and ensure project feasibility.

Step-by-Step Procedures in a Take-Off Service

The take-off process typically follows a structured sequence. First, project plans and specifications are thoroughly reviewed. This ensures a complete understanding of the scope of work. Then, measurements are taken based on the blueprints and detailed drawings. Accurate measurements are the foundation of a reliable take-off. Subsequently, data is compiled and organized. This organized data is essential for accurate calculations. Finally, a detailed report is generated, summarizing the quantities of materials and labor required for the project. This report forms the basis for cost estimations and subsequent project planning.

Role of Measurement Tools and Techniques

Accurate measurements are critical for successful take-offs. Different tools and techniques are employed depending on the project complexity and the types of materials involved. For example, measuring tapes, laser scanners, and digital surveying equipment are often used to determine dimensions of structures, areas, and volumes. Using these tools effectively minimizes errors and ensures the reliability of the take-off. Understanding the specific applications of each tool is key to producing accurate results.

Quality Control Measures in Take-Off Services

Quality control is paramount in construction take-off services. One critical aspect is the verification of measurements. This involves double-checking measurements and comparing them against different sources. For instance, cross-referencing blueprints with physical site measurements ensures consistency and reduces potential errors. Another important aspect is the use of standardized procedures. Using established processes for data entry, calculation, and reporting minimizes variations and enhances reliability.

Types of Measurement Tools and Their Applications

| Measurement Tool | Application in Take-Off Services |

|---|---|

| Measuring Tapes | Measuring linear dimensions of walls, columns, beams, and other linear elements. |

| Laser Scanners | Rapidly capturing 3D models of complex structures, facilitating the measurement of complex shapes and volumes. |

| Digital Surveying Equipment (Total Stations) | Precisely measuring distances, angles, and elevations for complex site surveys, vital for large-scale projects or uneven terrains. |

| Area Calculators (Software) | Determining the areas of various shapes, like roofs, floors, or irregular sections. |

| Volume Calculators (Software) | Calculating volumes of concrete, earthwork, or other materials with complex shapes, often used for excavation or foundation calculations. |

| Leveling Instruments | Precisely measuring differences in elevation between points on a site, critical for accurate earthwork calculations and ensuring proper drainage. |

Benefits and Advantages of Utilizing Take-Off Services

Hiring a dedicated take-off team significantly streamlines construction projects, bringing numerous benefits for various project phases. These services aren’t just about gathering data; they provide a crucial foundation for accurate cost estimations, efficient scheduling, and proactive risk management.

Accurate data collection and analysis are vital to successful project completion. Take-off services offer specialized expertise, ensuring the precision needed for sound decision-making. By utilizing these services, projects benefit from greater control over costs and timelines, reducing the likelihood of unexpected setbacks.

Cost Estimation and Budgeting Advantages

Accurate take-offs are the cornerstone of sound cost estimations. Professional take-off services leverage specialized software and experience to meticulously measure and quantify materials, labor, and equipment needs. This meticulous process leads to highly accurate cost estimations, empowering project managers with the precise figures necessary for robust budgeting. Furthermore, this precision minimizes the potential for significant cost overruns and ensures the project stays within the allocated budget. Take-off services also identify potential cost-saving opportunities through the analysis of alternative materials or techniques, further enhancing the accuracy of the budget.

Project Scheduling Advantages

Precise take-off data directly impacts project scheduling. By providing a comprehensive understanding of material quantities and labor requirements, take-off services enable project managers to create realistic and achievable schedules. Detailed material delivery schedules can be integrated into the overall project timeline, minimizing potential delays and ensuring the project stays on track. For example, a thorough take-off will precisely identify the sequence and duration of various tasks, contributing to a more accurate and efficient project schedule. This clarity leads to improved resource allocation and optimized workflow.

Risk Mitigation Advantages

Take-off services play a crucial role in identifying potential risks early in the project lifecycle. Comprehensive take-offs often uncover hidden complexities or potential issues that might otherwise be overlooked. For instance, identifying an unusual material requirement early on can enable the project team to proactively source the material, potentially mitigating delays and cost overruns. Furthermore, detailed take-offs often expose potential material shortages or supply chain disruptions, allowing for contingency planning. This proactive approach helps mitigate risks and ensures a smoother project execution.

Challenges and Considerations in Take-Off Services

Source: proficientest.com

Construction take-off services, while offering significant advantages, come with inherent challenges. Accuracy is paramount, as even small errors can escalate into substantial cost overruns or delays. Understanding these potential pitfalls and the importance of robust data management is crucial for successful project execution.

Accurate and reliable data forms the bedrock of a successful take-off. Errors, however minute, can lead to significant discrepancies in project estimations, potentially impacting the entire project lifecycle. Mitigation strategies and a thorough understanding of these challenges are essential to maintain project profitability and timeline adherence.

Potential Challenges in Take-Off Services

Several factors can pose obstacles in the take-off process. Inaccurate or incomplete project specifications, differing interpretations of design drawings, and the use of outdated or inappropriate material pricing data all contribute to the challenge of creating a precise take-off. Furthermore, handling complex projects with numerous components or intricate designs often presents unique difficulties in accurately estimating quantities. The sheer volume of data to be processed can overwhelm even the most sophisticated take-off systems, potentially leading to errors and delays. Furthermore, maintaining consistency and accuracy throughout a large-scale project is a considerable challenge.

Importance of Accurate and Reliable Data

Accurate data is the cornerstone of precise take-off. Inaccurate quantities directly translate into inaccurate project estimations. Small errors in quantities can easily accumulate, leading to significant discrepancies in the overall project budget. Consider a project involving 1000 square meters of flooring. A 5% error in the take-off would result in an underestimation of 50 square meters of flooring. This seemingly small discrepancy could have a large impact on the overall cost and timeline. Furthermore, errors in material specifications or dimensions can also lead to substantial cost overruns and quality issues.

Impact of Errors in Take-Off Services on Project Outcomes

Errors in take-off services can significantly impact project outcomes. Underestimation of material quantities can lead to shortages, necessitating costly last-minute purchases and delaying the project. Overestimation can result in unnecessary expenditures, impacting profitability. Furthermore, errors in labor estimations can lead to workforce scheduling issues and project delays. Consider a project requiring 1000 hours of labor. A 10% overestimation in the labor hours could mean paying for 1100 hours of labor, a substantial increase in costs without added value.

Potential Solutions to Common Challenges in Take-Off Services

Several strategies can help mitigate these challenges:

- Employing advanced software tools: Modern software solutions offer automation features, detailed material databases, and error-checking capabilities. These tools can significantly enhance the efficiency and accuracy of take-off services.

- Validating data sources: The accuracy of the take-off heavily relies on the reliability of the data sources. Thorough validation of all data, including specifications, drawings, and material pricing, is critical.

- Implementing rigorous quality control measures: Establishing clear procedures and protocols for data entry, review, and validation helps ensure accuracy and consistency throughout the entire take-off process. This includes having multiple people review the take-off to catch errors and maintain quality.

- Maintaining a comprehensive material database: A well-maintained database of materials with accurate specifications and current pricing ensures consistency and minimizes errors.

- Regular training and professional development for staff: Investing in the skills and knowledge of take-off personnel can lead to improved accuracy and efficiency.

Take-Off Service in Different Construction Sectors: Construction Take Off Services

Construction take-off services are crucial for accurate cost estimations in various sectors. Different projects have unique materials and labor requirements, making a standardized approach insufficient. Tailoring take-off procedures to the specific project type ensures precise cost calculations and effective resource allocation.

Take-off services adapt to the unique demands of each construction sector, from residential houses to massive industrial complexes. Understanding these sector-specific nuances is key to producing reliable and accurate estimates. The methods used for take-off differ based on the complexity and scale of the project, requiring a nuanced approach to ensure precise measurements and cost estimations.

Residential Construction Take-Off

Residential projects, like houses and apartments, often involve smaller-scale projects with a focus on precise material quantities. The take-off process typically involves meticulous measurement of each room and component, accounting for detailed specifications like wall thickness and window sizes. A high degree of accuracy is necessary to minimize material waste and ensure the project stays within budget. Software tools can assist in calculating quantities for various items, such as flooring, fixtures, and insulation.

Commercial Construction Take-Off

Commercial projects, such as office buildings and retail spaces, involve more complex designs and larger quantities of materials. Take-off services for these projects need to consider intricate architectural plans, extensive specifications, and varied material types. Detailed plans and specifications are crucial for accurate estimations. The process often relies on specialized software to manage large datasets and handle complex calculations.

Industrial Construction Take-Off

Industrial construction projects, including factories and warehouses, necessitate a comprehensive approach to take-off services. The scale of these projects is often significant, involving heavy machinery, specialized materials, and potentially unique structural designs. The take-off process needs to precisely calculate materials for large areas, complex equipment installations, and specific structural elements. Detailed blueprints and material lists are essential for accurate cost estimations.

Specialized Construction Areas Take-Off

Specialized construction areas, like bridges, tunnels, or high-rise buildings, require specialized take-off services due to unique design and material requirements. Specific design features, like unique structural elements or specialized materials, necessitate tailored take-off procedures. Detailed calculations and estimations are needed to ensure the safety and structural integrity of the project. Experienced professionals with expertise in the specific construction type are crucial.

Typical Project Types and Take-Off Needs

| Project Type | Specific Take-Off Needs |

|---|---|

| Residential House | Precise measurements of each room; detailed specifications for fixtures and finishes; focus on minimizing material waste. |

| Office Building | Accurate calculations for large-scale materials; management of complex architectural plans; consideration of varied material types. |

| Factory | Comprehensive calculations for large areas; detailed estimations for equipment installations; accurate calculation of materials for specific structural elements. |

| High-Rise Building | Specialized take-off procedures for unique structural designs; detailed calculations for structural elements and specialized materials. |

| Bridge Construction | Specific calculation of materials for complex structures; specialized calculations for structural elements. |

Technological Advancements in Take-Off Services

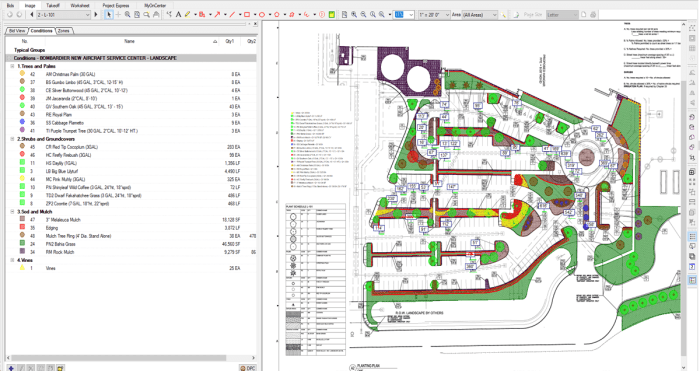

Source: globalintegra.com

Construction take-off services are rapidly evolving thanks to technological advancements. These innovations are streamlining workflows, boosting accuracy, and reducing costs across various construction sectors. This shift is driven by a need for greater efficiency and precision in a field where accurate estimations are crucial.

Technological advancements are significantly impacting construction take-off services. The use of software, automation, and data analysis is transforming how projects are planned and executed, leading to faster and more accurate results. These tools are not just replacing manual processes; they’re enabling new levels of efficiency and detail in project planning.

Impact of Technology on Take-Off Services

Technology is changing the landscape of construction take-off services. Digital tools are increasingly replacing manual methods, enabling quicker and more accurate estimations. The use of 3D modeling and BIM (Building Information Modeling) software is a prime example of this shift, providing detailed information for accurate take-offs. The impact is profound, leading to better project planning and management.

Examples of Automated Take-Off Software

Several software solutions are designed for automated take-off services. These tools leverage algorithms and data to calculate material quantities, reducing manual errors and increasing speed. Some prominent examples include:

- Take-off software specialized in different materials: Many programs are specialized in particular material types. For instance, there are software solutions specifically for steel, concrete, or wood. These specialized programs offer a higher degree of accuracy and efficiency for particular construction projects.

- BIM-integrated software: Building Information Modeling (BIM) software often includes features for automated take-offs. By importing building designs in digital format, these programs extract material quantities directly from the model, leading to fewer errors and greater efficiency.

- Cloud-based platforms: Cloud-based platforms allow multiple project stakeholders to access and share take-off data in real-time. This fosters collaboration and improves project management.

Advantages of Adopting Technology in Take-Off Services

Adopting technology in take-off services brings numerous advantages. The key benefits include:

- Reduced errors: Automation significantly minimizes human errors, ensuring greater accuracy in material estimations.

- Increased speed: Automated take-offs significantly reduce the time needed to complete estimations, allowing for faster project planning and execution.

- Improved accuracy: Technology ensures greater accuracy in material quantities, resulting in more realistic project budgets and schedules.

- Enhanced collaboration: Cloud-based platforms and BIM tools facilitate collaboration among project stakeholders, enabling real-time data sharing and updates.

Future Trends in Construction Take-Off Services

Future trends in construction take-off services are driven by the continuing development of advanced technologies. These trends include:

- AI-powered take-offs: Artificial intelligence (AI) is likely to play a more significant role in automating take-offs. AI algorithms can analyze large datasets and predict material needs with even greater precision.

- Integration with other construction technologies: Future take-off services will likely integrate more seamlessly with other construction technologies like drones and 3D printing. This integration will enhance project visualization and planning.

- Predictive modeling for material forecasting: Sophisticated algorithms will analyze historical data and market trends to predict material prices and availability, improving project cost estimations.

Take-Off Service Case Studies

Real-world applications of take-off services often highlight their value in streamlining construction projects. These case studies reveal how careful planning and execution, facilitated by accurate take-off data, can significantly impact project timelines and budgets. Understanding the successes and challenges in these applications can provide valuable lessons for future projects.

Successful Project Applications

Implementing accurate take-off services is crucial for cost estimation and resource allocation. Several projects have demonstrated how effective take-off services lead to improved project outcomes. A well-executed take-off process can identify potential risks and bottlenecks early in the project lifecycle.

Case Study 1: The Grand Plaza Renovation

This project involved renovating a large public plaza. Initial estimations, lacking detailed take-off data, underestimated the amount of concrete required for the walkways. This led to significant delays and increased costs. A specialized take-off service, using advanced laser scanning and BIM (Building Information Modeling) software, provided precise measurements and material quantities. This allowed for accurate material ordering and efficient labor allocation. The precise take-off data led to a 15% reduction in material waste and a 10% decrease in project completion time.

Case Study 2: The Coastal Housing Development

This project involved constructing 50 luxury beachfront homes. The complex topography and varying site conditions presented significant challenges. Traditional take-off methods struggled to account for the irregular terrain and specialized foundation requirements. Using a comprehensive take-off service, employing drone surveys and specialized software for irregular shapes, provided precise quantities for excavation, reinforcement, and construction materials. The project adhered to the budget and schedule, exceeding client expectations due to the optimized resource allocation.

Case Study 3: The Municipal Bridge Project

This project aimed to replace an aging bridge. The project involved complex structural components and required accurate material calculations for reinforcing steel, concrete, and other specialized materials. The team utilized a take-off service specializing in structural engineering. This service employed sophisticated CAD (Computer-Aided Design) software and expert engineers. The accurate take-off data allowed for efficient material procurement and construction, resulting in a 20% reduction in overall project costs.

Summary Table, Construction take off services

| Case Study | Project | Challenges | Solutions | Outcomes |

|---|---|---|---|---|

| Grand Plaza Renovation | Public Plaza Renovation | Underestimated concrete requirements | Advanced laser scanning and BIM software | 15% reduction in material waste, 10% decrease in project time |

| Coastal Housing Development | Luxury Beachfront Homes | Irregular terrain and site conditions | Drone surveys and specialized software for irregular shapes | Adhered to budget and schedule, exceeded client expectations |

| Municipal Bridge Project | Bridge Replacement | Complex structural components | Sophisticated CAD software and expert engineers | 20% reduction in overall project costs |

Closing Notes

In conclusion, construction take-off services are indispensable tools for project success. By accurately determining material needs and costs, these services empower construction professionals to make informed decisions regarding budgeting, scheduling, and risk management. From basic principles to advanced technological applications, this guide has explored the diverse facets of these vital services. We’ve seen how they’re crucial across different sectors and how technology is transforming the process. Ultimately, mastering construction take-off services is vital for staying ahead in today’s competitive construction landscape.