Construction Take-Off Services A Comprehensive Guide

Construction take off services – Construction take-off services are crucial for any project, from small renovations to massive skyscrapers. They’re the backbone of accurate budgeting, efficient scheduling, and ultimately, project success. This guide dives deep into the world of construction take-offs, exploring everything from defining the service to understanding the future trends shaping this industry.

This detailed exploration of construction take-off services will cover various types of take-offs, the methods used, and the crucial components of a successful take-off. We’ll also examine the benefits of using these services, the tools and technologies involved, potential challenges, and even case studies highlighting their real-world applications. From manual methods to advanced software, we’ll analyze the evolution of this field and what to expect in the future.

Defining Construction Take-Off Services

Source: masterestimators.com

Construction take-off services are crucial for any construction project. They involve the detailed estimation of materials and labor required for a specific project. This meticulous process ensures accurate cost projections, enabling project managers to make informed decisions and stay within budget. A well-executed take-off process also helps prevent costly delays and unforeseen issues.

Take-off services encompass a wide range of tasks, from precisely calculating the amount of lumber needed for framing to estimating the hours of labor required for excavation. These calculations are essential for creating a comprehensive budget and schedule for the project.

Types of Take-Off Services

Take-off services are categorized into different types, each tailored to a specific aspect of the project. Material take-offs determine the quantity of various construction materials, like concrete, steel, and wood. Labor take-offs, on the other hand, focus on estimating the number of hours of work needed from different trades, such as electricians, plumbers, and carpenters. Other specialized take-off services may also include equipment take-offs, focusing on the hours of use and costs of specific equipment.

Methods of Performing Take-Offs

The methods used for construction take-offs have evolved significantly, offering a choice between traditional and modern approaches. Manual take-offs, relying on manual calculations and measurements, are still used in some projects. However, automated take-offs are increasingly popular, utilizing software and digital tools for greater efficiency and accuracy.

Comparison of Manual and Automated Take-Off Methods

The choice between manual and automated take-off methods hinges on several key factors, as detailed in the table below.

| Feature | Manual Take-Off | Automated Take-Off |

|---|---|---|

| Data Entry | Requires manual input of measurements and quantities. | Data is automatically collected from drawings and specifications. |

| Accuracy | Prone to errors due to manual calculations and potential misinterpretations of drawings. | Higher accuracy due to automated calculations and reduced human error. |

| Speed | Significantly slower, especially for large projects. | Faster, particularly for large and complex projects, allowing for quicker turnaround times. |

| Cost | Generally lower initial investment but can be more costly in the long run due to increased labor time and potential errors. | Higher initial investment for software and training but offers potential for lower long-term costs due to reduced errors and faster turnaround. |

Benefits of Using Construction Take-Off Services

Construction take-off services are invaluable tools for project success. They streamline the initial stages of a project, enabling more accurate estimations and better-informed decisions throughout the entire process. This translates to significant savings and improved project outcomes.

Take-off services provide a systematic approach to quantifying materials needed for a construction project. This precise quantification is the foundation for reliable budgeting, accurate scheduling, and ultimately, a more profitable project. By automating and standardizing the process, they minimize errors and ensure that project stakeholders have the most up-to-date and reliable information possible.

Improved Project Budgeting and Cost Estimation

Accurate material quantities are the cornerstone of sound project budgeting. Construction take-off services provide a comprehensive list of materials, their quantities, and associated costs. This data allows for precise cost estimations, helping project managers create realistic budgets and avoid potential cost overruns. A detailed take-off report can also highlight potential cost savings by comparing different material options or sourcing strategies. This data-driven approach to budgeting significantly improves the project’s financial planning and reduces the likelihood of unexpected expenses.

Enhanced Project Scheduling

Construction take-offs directly impact project scheduling. Knowing the exact quantities of materials needed allows project managers to accurately estimate the time required for procurement, delivery, and on-site installation. This leads to a more realistic and dependable project schedule. For example, if a take-off reveals a significant amount of a specific material that’s in short supply, the project team can adjust the schedule accordingly to avoid delays. This proactive approach, facilitated by precise take-off data, ensures timely completion of the project. By precisely accounting for time and material requirements, project timelines become more manageable and predictable.

Examples of Projects Benefiting from Construction Take-Offs

Numerous projects have relied on construction take-offs for success. A highway expansion project, for example, used take-off services to precisely calculate the amount of asphalt, concrete, and steel required. This precise quantification allowed the project team to create a detailed budget and schedule, ultimately leading to the project’s timely and within-budget completion. Similarly, a large-scale residential development utilized take-off services to accurately determine the quantities of lumber, drywall, and other materials. This accurate estimation of materials helped avoid costly material shortages and ensured the project remained on schedule and within budget. These examples illustrate how construction take-offs are critical for managing complexity and maintaining control over project costs and timelines.

Key Components of a Construction Take-Off

A construction take-off is the foundation of any successful project. It’s the meticulous process of determining the exact quantities of materials needed for a construction project. A thorough take-off ensures accurate cost estimations, efficient material procurement, and ultimately, project profitability. It’s the critical first step that sets the stage for the entire construction process.

A comprehensive take-off goes beyond simply counting; it involves understanding the project’s design, the materials’ specifications, and the relevant construction techniques. This detailed analysis ensures that all necessary components are accounted for, preventing costly omissions or overages. It’s a critical step to manage costs effectively.

Essential Elements of a Comprehensive Take-Off

A complete take-off meticulously gathers data from various sources, providing a comprehensive picture of the project’s material requirements. This includes not only the quantity of materials but also their specific types, sizes, and unique specifications. This detail-oriented approach ensures a precise understanding of the materials needed for the project.

- Project Drawings: Detailed blueprints, architectural drawings, and structural plans are the primary sources for the take-off process. These visual representations provide crucial information about the project’s layout, dimensions, and material specifications. Accurate interpretation of these drawings is essential for an accurate take-off.

- Specifications: Detailed material specifications provide crucial data on the exact types, grades, and dimensions of materials required. They are critical in ensuring the project meets quality standards and avoids potential issues during construction.

- Quantity Surveying Data: Existing data on previous similar projects or standard quantities for typical construction elements can significantly expedite the take-off process. It provides a baseline to compare and refine the current project’s estimations.

- Site Conditions: Understanding the site’s topography, existing utilities, and any special conditions can impact material requirements. This aspect might involve adding materials for site preparation or adjusting quantities for specific site constraints.

Types of Drawings and Documents Used for Take-Offs

Different types of drawings provide unique insights into the project. Careful analysis of these documents ensures no aspect of the construction is overlooked during the take-off process.

- Architectural Drawings: These plans detail the building’s exterior and interior design, showing walls, windows, doors, and other features. They’re vital for calculating quantities of materials like drywall, doors, and windows.

- Structural Drawings: These drawings provide information about the building’s structural components, including beams, columns, and foundations. They are crucial for determining the quantities of concrete, steel, and other structural materials.

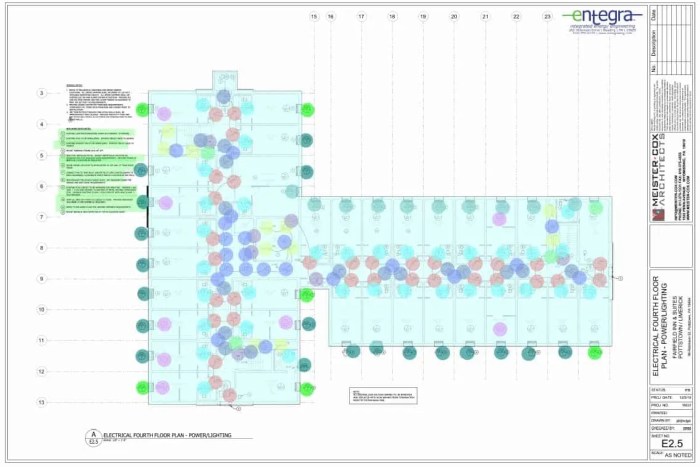

- Plumbing and Electrical Drawings: These drawings show the location and layout of plumbing and electrical fixtures and conduits. They help determine the quantity of pipes, wires, and fittings needed.

- Site Plans: These plans depict the project’s location on the site, showing boundaries, existing features, and utility locations. They’re important for estimating earthwork, fencing, and other site-specific materials.

Gathering and Interpreting Data for a Take-Off

The accuracy of the take-off relies heavily on careful data collection and interpretation. The steps involved ensure that all necessary data is collected accurately.

- Data Extraction: Accurate measurements from drawings are crucial. Using precise measuring tools and techniques ensures accurate calculations. This process requires attention to detail and accuracy to avoid errors.

- Data Validation: Cross-checking extracted data against specifications is crucial. This step helps ensure the accuracy of the collected data and minimizes potential errors.

- Data Entry: A consistent and organized method for recording data is essential. Using software or spreadsheets facilitates efficient data management. This helps ensure that the data is organized and easily accessible for analysis.

- Review and Revision: A review of the gathered data and calculations is crucial to identify and correct potential errors. This step helps ensure accuracy and consistency in the take-off.

Typical Data Points Extracted from Drawings

A thorough take-off process involves extracting various data points from the drawings. These data points are crucial for estimating quantities and costs.

| Drawing Type | Data Point |

|---|---|

| Architectural | Number and dimensions of windows, doors, and walls |

| Structural | Dimensions and quantities of beams, columns, and foundations |

| Plumbing | Length of pipes, number of fixtures, and valve types |

| Electrical | Length of wiring, number of outlets, and switch types |

Tools and Technologies in Take-Off Services: Construction TTake-OffServices

Construction take-offs are no longer solely reliant on manual calculations. Modern tools and technologies have revolutionized the process, making it faster, more accurate, and more efficient. These tools not only speed up the initial stages but also reduce errors, leading to better project estimations and overall cost control.

Current take-off methods leverage digital platforms to streamline the process. Software solutions are designed to manage large datasets of materials, simplifying the entire take-off procedure. This digital approach enables project managers to accurately track and analyze material requirements, ultimately contributing to more precise project budgets.

Current Tools and Software for Construction Take-offs

Various software programs are now available for construction take-offs, catering to different project sizes and needs. These programs automate many manual tasks, improving efficiency and reducing the risk of human error. From simple spreadsheets to sophisticated software packages, the choice depends on the complexity of the project and the user’s familiarity with the tools.

Comparison of Popular Take-Off Software Programs

Different take-off software programs have unique strengths and weaknesses. Some specialize in handling specific types of projects or materials, while others offer a more comprehensive suite of features. Choosing the right program depends on the specific needs of the project, the user’s skill level, and the project’s scale. Comparing programs side-by-side allows for a more informed decision.

Cloud-Based Take-Off Solutions

Cloud-based take-off solutions have become increasingly popular. These solutions provide access to data from anywhere with an internet connection, facilitating collaboration among project teams. This accessibility empowers project managers and team members to work together in real-time, sharing information and updating data as needed. Cloud solutions also often offer improved security and data backup compared to on-premise solutions. Furthermore, they allow for easy scalability, accommodating growing project needs without significant infrastructure changes.

Key Features of Popular Take-Off Software

This table highlights key features of several popular construction take-off software programs. It provides a comparative overview of their functionalities, pricing models, and user reviews. This helps in making a well-informed choice based on specific project requirements.

| Software | Features | Pricing | User Reviews |

|---|---|---|---|

| Software A | Detailed material libraries, automated calculations, accurate take-off for various construction types, integration with other project management software, and cloud-based options. | Starts at $X per month/user, with tiered pricing for increased users and features. | Generally positive, highlighting accuracy and efficiency gains. Some users report a learning curve for complex projects. |

| Software B | User-friendly interface, customizable templates for repetitive tasks, good support resources, and a range of calculation options for diverse material types. | Subscription-based, with options for individual users and teams. Pricing varies based on the chosen package. | Positive feedback on the user-friendliness, with some users noting room for improvement in reporting and advanced analysis tools. |

| Software C | Advanced BIM integration, detailed cost estimation capabilities, and extensive material databases for different regions. | High-end pricing, usually project-based or annual licensing. | Highly rated for accuracy and in-depth analysis, often preferred for large-scale and complex projects. The high price point is a drawback for smaller projects. |

Challenges and Considerations in Take-Off Services

Source: worldestimating.com

Construction take-off services, while crucial for accurate project estimations, face inherent challenges. These challenges often stem from the complexity of projects, the variability of materials, and the need for meticulous attention to detail. Overcoming these hurdles requires a combination of skilled personnel, robust processes, and up-to-date technologies.

Common Challenges in Take-Off Processes

Accurately estimating quantities of materials and labor for construction projects is a complex task. Common hurdles include inconsistent project specifications, unclear drawings, and difficulties in accessing precise information about site conditions. Changes in design during the project lifecycle also frequently necessitate revisions to the take-off, introducing delays and potential errors. Furthermore, the availability and cost of materials can fluctuate, requiring constant monitoring and adjustments to the initial estimates. Finally, the potential for human error, especially in large or complex projects, is a significant factor.

Importance of Accuracy and Precision in Take-Offs

Precise take-offs are fundamental to successful construction projects. Inaccurate estimations can lead to significant cost overruns, delays, and even project failure. A minor error in calculating the quantity of concrete, for example, can translate into thousands of dollars in extra expenses. Accurate take-offs form the bedrock of realistic project budgets, enabling informed decision-making throughout the project lifecycle. A well-executed take-off allows for accurate cost analysis, risk assessment, and the establishment of realistic project timelines.

Role of Experience and Expertise in Accurate Take-Offs

Experienced take-off professionals possess a deep understanding of construction materials, methods, and industry standards. Their knowledge allows them to interpret blueprints, specifications, and site conditions with greater accuracy. Expertise facilitates the identification of potential issues or discrepancies early in the process, enabling proactive mitigation strategies. This knowledge base reduces the likelihood of errors and ensures the take-off aligns with project requirements. Furthermore, experience in handling various construction types and projects builds valuable judgment skills, crucial for identifying potential problems and adjusting estimations accordingly. For instance, a seasoned take-off technician can quickly spot inconsistencies in architectural drawings that a novice might miss.

Need for Proper Training and Certification for Take-Off Professionals

Construction take-off personnel require thorough training to ensure accuracy and efficiency. Training programs should cover various aspects of construction materials, methods, and standards, including a detailed understanding of blueprints, specifications, and site surveys. Certification validates a professional’s knowledge and competency in performing take-off tasks. Certified take-off professionals demonstrate adherence to industry best practices, ensuring the quality and reliability of their work. Such training enhances the overall quality of take-off services, reducing the risk of errors and increasing the likelihood of accurate project estimations. Moreover, ongoing professional development is essential for staying current with industry advancements and emerging technologies.

Future Trends in Construction Take-Off Services

Construction take-off services are constantly evolving, driven by the relentless march of technology. This evolution promises to dramatically alter how projects are estimated and managed, offering significant improvements in speed, accuracy, and overall efficiency. From sophisticated software to automated data capture, the future is brimming with innovations that will reshape the entire process.

Automation and AI Integration

The rise of artificial intelligence (AI) and machine learning (ML) is poised to revolutionize construction take-offs. AI algorithms can analyze vast datasets, including blueprints, specifications, and previous project data, to generate accurate take-offs with minimal human intervention. This automation promises to significantly reduce errors and speed up the process, freeing up project managers to focus on higher-level tasks.

Advancements in 3D Modeling and BIM

Building Information Modeling (BIM) is rapidly transforming the construction industry. 3D models, a cornerstone of BIM, provide detailed representations of the project, making it easier to extract accurate quantities for take-offs. Software integrated with BIM platforms can automatically generate take-off data from the model, significantly improving accuracy and reducing the potential for human error. This technology allows for a comprehensive and precise understanding of the project, minimizing discrepancies between design and execution.

Drone-Based Surveying and Data Capture

Drones equipped with high-resolution cameras and laser scanners are revolutionizing site surveying. By capturing detailed aerial imagery and 3D point clouds, drones can quickly and accurately assess the project site. This data can then be used to automatically generate take-off information, eliminating the need for manual site measurements and significantly accelerating the entire process. This technology is especially valuable in complex or large-scale projects, where extensive site surveying would otherwise be time-consuming and costly.

Cloud-Based Platforms and Collaboration

Cloud-based platforms are facilitating greater collaboration and data sharing among project stakeholders. These platforms allow multiple team members to access and update project data in real time, enabling more efficient communication and improved coordination. Cloud-based take-off software allows for seamless collaboration across teams, regardless of location, ensuring that everyone has access to the most up-to-date information. This enhanced communication and accessibility will contribute significantly to streamlining workflows and project completion.

Case Studies and Real-world Applications

Source: estimatorflorida.com

Construction take-off services aren’t just theoretical concepts; they’re vital tools in the real world of project management. Seeing how these services have improved outcomes in various projects provides a clear understanding of their practical value. From smaller residential builds to massive infrastructure projects, take-offs are transforming how construction companies approach cost estimations and project planning.

Real-world applications of construction take-off services span diverse project types, demonstrating their adaptability and effectiveness. Accurate estimations, a key benefit of take-off services, translate directly into better project control and profitability.

Residential Construction Projects

Accurate take-offs are critical in residential projects, where precise material calculations directly impact profitability and customer satisfaction. A well-executed take-off helps builders accurately predict costs, enabling them to offer competitive pricing and manage material waste effectively. For example, a builder using take-off services for a new home could anticipate the precise amount of lumber, drywall, and other materials needed. This avoids costly material shortages during construction, keeping the project on schedule and budget.

Commercial Construction Projects

Commercial projects, with their intricate designs and diverse material needs, benefit greatly from meticulous take-offs. Accurate calculations help prevent project overruns by precisely estimating the cost of materials, labor, and equipment. Imagine a large office building project – take-off services would meticulously detail the quantity of steel, concrete, and specialized finishes required. This level of detail ensures the project remains on schedule and within budget, minimizing costly surprises and maximizing profitability.

Infrastructure Projects, Construction take-off services

Infrastructure projects, encompassing roads, bridges, and utilities, often involve massive quantities of materials. Precise take-offs are essential to manage the substantial costs associated with these projects. A take-off service for a highway expansion project would meticulously calculate the volume of asphalt, concrete, and reinforcing steel needed. This detailed breakdown helps in effective resource allocation, enabling the project to stay within budget and meet project deadlines. Accurate material take-offs are vital for the success of such large-scale endeavors.

Specific Examples of Improved Project Outcomes

A construction company, using a take-off service for a 100-unit apartment complex, reduced material costs by 15% and completed the project two weeks ahead of schedule. Another company, taking on a large commercial renovation, saw a 10% reduction in overall project expenses by precisely calculating the needed materials. These are just two examples of how careful take-off services translate into concrete, positive results.

Types of Construction Projects Utilizing Take-Off Services

Source: digitalestimating.com

Construction take-off services are incredibly versatile, aiding a wide range of projects. They’re not just for massive skyscrapers; smaller projects and specialized tasks also greatly benefit from a meticulous take-off. From initial estimations to detailed material lists, take-off services streamline the entire process.

Take-off services are instrumental in optimizing project planning and resource allocation. By accurately quantifying materials needed, they enable contractors to create realistic budgets, project timelines, and labor requirements. This translates to better cost control, improved scheduling, and minimized project risks.

Residential Construction Projects

Residential projects, from single-family homes to apartment complexes, often utilize take-off services. Detailed take-offs are crucial for accurate material ordering and cost estimations. This is especially true for custom homes with unique designs or renovations requiring specific materials. Project scales vary considerably, from small additions to entire new developments.

Commercial Construction Projects

Commercial projects, including office buildings, retail spaces, and warehouses, rely heavily on take-off services for precise material calculations. The complexity of these projects, involving numerous structural elements, mechanical systems, and finishes, necessitates detailed take-offs to ensure efficient material procurement and avoid costly delays. These projects often involve a significant number of materials, making accurate take-offs essential for cost control and project feasibility. The scale of these projects can range from small renovations to large-scale developments requiring hundreds of thousands of square feet.

Infrastructure Projects, Construction take-off services.

Infrastructure projects, such as roads, bridges, and public utilities, often require extensive take-off services. These projects are characterized by large-scale construction, requiring massive quantities of materials, from concrete and steel to asphalt and piping. Accurate take-offs are vital to manage significant costs and ensure timely completion. The scale can vary from a small bridge replacement to an extensive highway expansion project.

Industrial Construction Projects

Industrial construction projects, encompassing factories, manufacturing facilities, and warehouses, demand detailed take-offs for precise material quantification. The complexity of these projects, with specialized equipment and systems, necessitates a comprehensive take-off to avoid material shortages or overstocking. The scale varies significantly, from small expansions to massive new facilities, potentially requiring thousands of tons of steel and concrete.

Renovation and Repair Projects

Renovations and repairs, whether in residential or commercial settings, also benefit from take-off services. Accurate take-offs help determine the exact amount of materials required for the specific task, whether it’s replacing flooring, upgrading electrical systems, or completing a full-scale remodeling. The scale of these projects can range from a small kitchen remodel to a complete building restoration. These services are especially crucial in determining cost-effective solutions for repairs.

Specific Situations Recommending Take-Off Services

- Complex Designs: Projects with intricate designs, unique architectural elements, or specialized materials benefit significantly from a thorough take-off. This allows for precise material quantification, avoiding errors and ensuring the project adheres to the specifications.

- Multiple Contractors: Projects involving multiple contractors require precise material lists to prevent duplication and conflicts in material ordering. A take-off ensures clear communication and avoids discrepancies.

- Tight Budgets: In projects with constrained budgets, accurate take-offs are essential to avoid exceeding the allocated funds. A thorough take-off enables the selection of cost-effective materials and prevents material waste.

- Strict Timelines: Projects with tight deadlines rely on precise material quantification. Take-off services allow for efficient material ordering and delivery, ensuring the project remains on schedule.

Last Recap

In conclusion, construction take-off services are more than just a process; they’re a critical element in successful project management. Understanding the various aspects, from the initial definition to future advancements, empowers project managers to make informed decisions. By embracing accuracy, efficiency, and the latest technologies, projects can achieve their goals more effectively. The importance of accurate and timely take-offs cannot be overstated in today’s construction landscape.