Electrical Estimation and Contracting A Complete Guide

Electrical estimation and contracting is crucial in the construction industry. It involves everything from initial project planning to final completion, encompassing budgeting, material selection, labor scheduling, and regulatory compliance. This guide provides a comprehensive overview of the entire process, highlighting key considerations and best practices.

We’ll explore various estimation methods, analyze electrical drawings and specifications, discuss material procurement, and delve into labor cost management. Project management strategies, legal contracts, and regulatory compliance will also be covered, ensuring a complete understanding of electrical contracting.

Introduction to Electrical Estimation and Contracting

Electrical estimation and contracting is a crucial aspect of the construction industry. It involves accurately determining the cost of electrical work, managing the project from design to completion, and ensuring the safe and efficient installation of electrical systems. This process is vital for project profitability, timely completion, and adherence to safety standards. A well-executed electrical estimation and contracting process directly impacts the overall success of a construction project.

Accurate estimations and proper contracting practices minimize potential cost overruns and delays, ensuring projects are completed within budget and on schedule. This, in turn, builds trust with clients and fosters a positive reputation for the contracting firm. Understanding the various roles and responsibilities within the process, as well as the types of projects encountered, is essential for effective management.

Key Roles and Responsibilities

Electrical estimation and contracting involves a team of professionals with distinct roles and responsibilities. Estimators analyze project specifications, determine material requirements, and calculate the total cost of the electrical work. Contractors oversee the entire installation process, ensuring adherence to codes and timelines. Project managers coordinate the activities of the various teams and maintain communication with clients. Electricians, skilled tradespeople, are responsible for the actual installation of the electrical systems. Each role plays a critical part in the smooth execution of the project.

Types of Electrical Projects

The electrical contracting industry handles a wide array of projects. Residential projects include homes, apartments, and townhouses, demanding precise estimations for individual needs. Commercial projects cover office buildings, retail spaces, and restaurants, often requiring complex and extensive electrical systems. Industrial projects involve factories, warehouses, and manufacturing facilities, with unique electrical demands based on machinery and equipment. Infrastructure projects encompass the installation of power grids, substations, and lighting systems for public spaces. Each project type presents unique challenges and opportunities for electrical contractors.

Phases of an Electrical Project

Understanding the different phases of an electrical project is critical for efficient management and successful completion. The table below Artikels the typical phases, from initial planning to final completion.

| Phase | Description |

|---|---|

| Project Initiation | Defining project scope, gathering requirements, and obtaining necessary approvals. |

| Planning and Design | Creating detailed electrical plans, diagrams, and specifications, including load calculations and safety considerations. |

| Procurement | Purchasing materials and equipment needed for the project, considering factors like availability and cost-effectiveness. |

| Installation | Executing the installation of electrical systems according to plans, ensuring adherence to safety regulations and codes. |

| Testing and Commissioning | Verifying the functionality and safety of the installed systems, often involving comprehensive testing procedures. |

| Final Inspection and Acceptance | Obtaining final inspections from relevant authorities and client acceptance of the completed project. |

Estimating Methods and Procedures

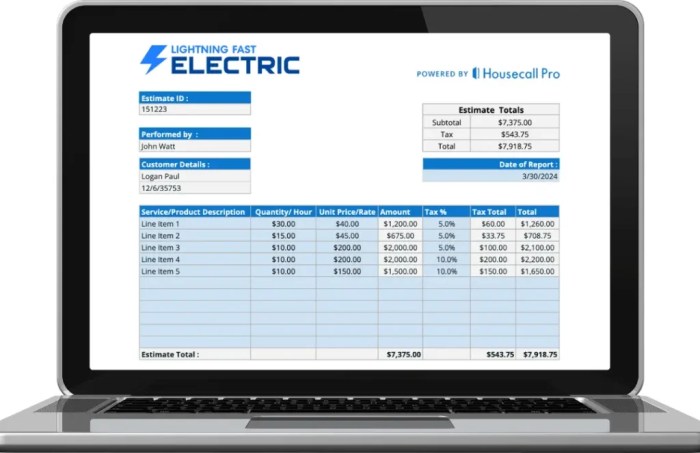

Electrical estimations are crucial for project success. Accurate estimations ensure profitability, timely completion, and client satisfaction. A well-structured estimation process involves understanding different methods, analyzing associated costs, and incorporating potential risks.

Understanding various estimation techniques and their strengths and weaknesses is key to selecting the most appropriate approach for each project. This includes knowing how to calculate material costs, labor expenses, and overhead, and incorporating contingency plans for unforeseen circumstances. This comprehensive guide will Artikel different methods, illustrate the estimation process, and highlight the importance of contingencies.

Different Estimation Methods

Various methods exist for electrical estimations. Each method has its own advantages and disadvantages, influencing the accuracy and efficiency of the process. Common methods include the unit-cost method, the quantity surveying method, and the parametric method.

- Unit-cost method: This method involves determining the cost per unit of a specific material or task. Multiplying the unit cost by the quantity required provides a total cost. It’s straightforward and quick, making it suitable for small projects with readily available unit costs. However, it may not account for complex project specifics or variable labor costs.

- Quantity surveying method: This detailed approach involves a comprehensive breakdown of all materials and labor required for the project. Detailed drawings and specifications are analyzed to precisely determine quantities. It is highly accurate but time-consuming, typically employed for large and complex projects.

- Parametric method: This method uses pre-determined formulas or statistical models to estimate costs based on project parameters. It leverages historical data to predict costs and is relatively fast. Its accuracy depends on the reliability of the data used in the model. It is useful for projects with similar characteristics to previous projects.

Comparing Estimation Methods

Different estimation methods offer varying levels of accuracy and efficiency. Understanding these trade-offs helps in choosing the right approach.

| Method | Advantages | Disadvantages |

|---|---|---|

| Unit-cost | Simple, fast, suitable for small projects | May not account for project complexity, variable labor |

| Quantity surveying | Highly accurate, detailed breakdown | Time-consuming, not suitable for small projects |

| Parametric | Fast, uses historical data | Accuracy depends on data reliability, less detailed |

Steps in Creating an Accurate Electrical Estimate

Creating a precise estimate involves several steps. Careful attention to each step ensures a reliable estimate.

- Detailed Project Analysis: Thoroughly reviewing project specifications, drawings, and any additional requirements is crucial. This step ensures all necessary components are considered.

- Material Cost Calculation: Precisely determining material quantities and current market prices for materials like wire, conduit, and fixtures is essential. This includes checking for any discounts or bulk pricing.

- Labor Cost Estimation: Estimating the time required for different tasks, considering the experience level of the workforce, is essential. Labor rates must be accurately calculated and documented.

- Overhead Calculation: Overhead costs like administrative expenses, permits, and insurance must be factored into the estimate. A percentage of the total direct costs is usually used.

- Contingency Planning: Accounting for potential risks and uncertainties is vital. A contingency amount should be included to cover unforeseen circumstances.

- Review and Finalization: Thoroughly reviewing the entire estimate before finalization is crucial. This ensures accuracy and completeness. Double-checking calculations and validating the estimate against project specifications is important.

Cost Breakdown in an Electrical Estimate

A clear cost breakdown is vital for transparency and accountability. The table below provides a template.

| Item | Cost |

|---|---|

| Materials | $XX,XXX |

| Labor | $YY,YYY |

| Contingency | $ZZ,ZZZ |

| Total | $Total |

Incorporating Risks and Contingencies

Identifying potential risks and including contingency allowances in the estimate is crucial for project success. Historical data on similar projects and industry benchmarks can help in setting realistic contingencies.

A 10-15% contingency allowance is often used for electrical projects.

Electrical Drawings and Specifications

Electrical drawings and specifications are the blueprints for any electrical installation. They provide crucial information for estimators, guiding them through the entire process of calculating material needs, labor hours, and project costs. Accurate interpretation of these documents is paramount for a successful and profitable electrical contracting business.

These documents meticulously detail the layout, components, and required specifications for every electrical system. Without them, an estimator is essentially working blind, leading to potential errors in material quantities and project timelines.

Significance in Electrical Estimation

Electrical drawings and specifications are vital for accurate estimation. They provide a complete picture of the electrical system, allowing estimators to determine the necessary materials, labor, and potential challenges. This comprehensive understanding is critical for precise cost estimations, realistic project scheduling, and ultimately, profitable contracts. By correctly interpreting the drawings and specifications, estimators can avoid costly mistakes and oversights.

Key Components in Electrical Drawings

Electrical drawings typically include schematics, wiring diagrams, and single-line diagrams. Schematics show the electrical circuits, while wiring diagrams illustrate the physical connections. Single-line diagrams represent the system’s components in a simplified, one-line representation, allowing for a broader overview. These drawings often incorporate details on the type and size of conductors, the locations of electrical devices, and the layout of the electrical system.

Types of Electrical Symbols

Electrical drawings utilize standardized symbols to represent various components. These symbols are internationally recognized and help to quickly and easily identify the specific equipment and their functions within the electrical system. Common symbols include those for switches, receptacles, lighting fixtures, transformers, and more. Understanding these symbols is crucial for interpreting the drawings accurately.

Interpreting Electrical Specifications

Electrical specifications detail the precise requirements for materials, installation methods, and safety standards. They often specify the type of wire, conduit, devices, and the required testing procedures. Estimators need to carefully analyze these specifications to ensure that the project complies with all relevant codes and regulations.

Table of Common Electrical Symbols

| Symbol | Description |

|---|---|

| A | Fuse |

| ∆ | Ground |

| □ | Switch |

| ■ | Receptacle |

| ∙ | Lamp |

| (Coil) | Transformer |

Elements to Consider When Interpreting Drawings and Specifications

- Codes and Regulations: All electrical installations must adhere to local, state, and national electrical codes. Estimators must ensure that the proposed work complies with these regulations to avoid costly revisions or legal issues.

- Material Specifications: Carefully examine the material specifications to determine the exact type, gauge, and length of conductors, conduit, and other components. Differences in these specifications can significantly impact the cost of materials.

- Installation Methods: The specifications often Artikel the required installation methods. Understanding these details is vital for accurately calculating labor hours and potential challenges during the installation phase.

- Device Ratings: Specifications often provide details on the ratings of electrical devices, such as voltage, current, and power capacity. Estimators need to ensure that the specified devices are appropriate for the application.

- Safety Considerations: Pay close attention to any safety-related specifications, including grounding requirements, protective measures, and clearances. Failing to account for safety factors can lead to costly rework and safety hazards.

Material Selection and Procurement

Picking the right materials is crucial for a successful electrical project. It’s not just about cost; you need materials that are reliable, safe, and meet the project’s specifications. This section dives into the factors influencing material selection, ensuring quality, the procurement process, and comparing different options.

Factors Influencing Material Selection

Several factors impact material choices in electrical projects. Budget constraints, project timelines, and the specific requirements of the job all play a part. Also, the quality of the materials directly affects safety and the long-term performance of the installation. Environmental considerations, like local regulations and sustainability concerns, are becoming increasingly important. Finally, the availability of materials in the local market and the vendor’s reputation also influence the decision-making process.

Importance of High-Quality Materials

Choosing high-quality and reliable electrical materials is paramount. This translates to a safer, more efficient, and longer-lasting installation. Poor-quality materials can lead to electrical faults, fires, and costly repairs down the line. Investing in reputable brands and certified products ensures the integrity and safety of the system. The lifespan of the entire installation will be significantly improved.

Material Procurement Process

The procurement process involves several steps. First, you need to create a detailed materials list based on the project plans. Next, research and compare different vendors and their pricing. Then, you need to consider lead times and ensure the vendor has the necessary certifications. Place orders carefully, considering delivery schedules, and confirm the received materials match the specifications. Finally, store materials properly to maintain their quality and prevent damage.

Comparing Prices and Availability

Comparing prices and availability is essential for making informed decisions. Use spreadsheets or online comparison tools to systematically record the prices and delivery times from various vendors. Consider not only the quoted price but also the potential extra costs for shipping and handling. Look at the vendor’s reputation and track record for prompt delivery and quality assurance.

Material Comparison Table

| Material Type | Features | Cost (USD) | Compliance with Codes |

|—|—|—|—|

| Copper Wire | Excellent conductivity, durability, and corrosion resistance | $1.50-$3.00 per foot | Meets NEC and local codes |

| Aluminum Wire | Lower cost, lighter weight | $0.75-$2.00 per foot | Meets NEC but may require different connectors |

| PVC Conduit | Durable, fire-resistant, and readily available | $0.50-$1.00 per foot | Meets NEC and local codes |

| Metal Conduit | High strength, suitable for harsh environments | $1.00-$2.50 per foot | Meets NEC and local codes |

| Electrical Boxes | Variety of sizes and types, for mounting devices | $5.00-$20.00 per box | Meets NEC and local codes |

Note: Prices are estimates and can vary depending on the quantity, vendor, and location.

Compliance with Electrical Codes and Regulations

Adhering to relevant electrical codes and regulations is mandatory. It ensures the safety and reliability of the electrical system. Consult the National Electrical Code (NEC) and local building codes for specific requirements. Ensure all materials used meet the required standards and have the necessary certifications. Penalties for non-compliance can be substantial. Furthermore, compliance safeguards the safety of building occupants and workers.

Labor Costs and Scheduling: Electrical Estimation And Contracting

Source: ravestimating.com

Labor costs are a significant component of any electrical contracting project. Accurate estimation and effective scheduling are crucial for profitability and project success. Understanding the factors influencing labor costs and developing a robust scheduling plan helps ensure projects stay on time and within budget.

Factors Impacting Labor Costs

Several factors influence labor costs in electrical contracting. These include labor rates, which vary based on experience, location, and demand. Skill-specific requirements also play a part; specialized electricians command higher rates. Project complexity significantly affects labor hours. More intricate installations require more time and specialized expertise, thus driving up costs. Material availability and logistical challenges can also impact labor costs, especially when delays or unexpected issues arise. Finally, overhead costs, such as insurance and administrative expenses, are also factored into overall labor costs.

Importance of Accurate Labor Scheduling

Accurate labor scheduling is essential for project success. Proper scheduling minimizes delays, ensures timely completion, and prevents costly overtime. It also helps optimize resource allocation, preventing underutilization or overworking of personnel. Well-planned schedules allow for adequate time for breaks, safety precautions, and unforeseen circumstances. This ultimately contributes to a smoother project workflow and a more predictable project timeline.

Estimating Labor Costs for Different Electrical Tasks

Estimating labor costs for specific electrical tasks involves breaking down the work into smaller, manageable components. This includes analyzing the specific materials needed, evaluating the complexity of the installation, and identifying any required permits or inspections. Detailed task breakdowns allow for a more precise estimate of the required labor hours. Consult previous projects and historical data for similar installations to gauge the average time spent on each stage.

Calculating Labor Hours for Various Electrical Jobs

Calculating labor hours for different electrical jobs involves considering the type of work, complexity, and required skill level. For instance, installing a standard circuit might take 2 hours, while installing a complex lighting system could take 10 hours or more. A table can help illustrate this:

| Task | Estimated Labor Hours |

|---|---|

| Wiring a standard circuit | 2-3 hours |

| Installing a complex lighting system | 8-12 hours |

| Installing a fire alarm system | 10-15 hours |

| Installing a high-voltage power system | 20+ hours |

Labor hour estimates should be realistic and account for potential delays or complications. A buffer for unforeseen circumstances is essential.

Managing and Monitoring Labor Costs Throughout a Project

Managing and monitoring labor costs throughout a project is vital. Tracking actual labor hours against estimated hours is essential. Regular reporting on progress against the schedule, identifying potential cost overruns, and making adjustments as needed are critical. Using project management software can streamline this process, offering real-time visibility into labor costs and progress. This allows for proactive interventions and mitigates potential cost escalations.

Implications of Labor Shortages on Project Timelines

Labor shortages can significantly impact project timelines. When skilled electricians are unavailable, projects face delays. This can lead to cost overruns and project completion being pushed back. Strategies for mitigating these effects include exploring alternative labor sources, such as temporary workers or subcontractors. Anticipating potential labor shortages during the planning stages can help mitigate the risk and maintain a realistic timeline.

Project Management and Control

Project management is crucial for electrical contracting. It ensures projects are completed on time, within budget, and to the required quality standards. Effective project management streamlines communication, manages risks, and fosters a productive work environment. Proper planning and control are vital for success in the often complex world of electrical installations.

Importance of Project Planning

Thorough project planning is the bedrock of successful electrical projects. It lays the groundwork for efficient execution and minimizes potential pitfalls. A well-defined plan Artikels tasks, responsibilities, timelines, and resource allocation. This clarity allows the team to work cohesively and prevents costly rework or delays.

Key Aspects of Project Planning, Execution, and Monitoring

Project planning involves defining project scope, identifying tasks, assigning responsibilities, establishing timelines, and allocating resources. Execution entails carrying out the planned tasks according to schedule and budget. Monitoring is the continuous process of tracking progress, identifying deviations, and taking corrective actions to maintain the project on track.

Strategies for Effective Communication and Collaboration

Effective communication is essential for a successful electrical contracting team. Regular meetings, clear documentation, and readily accessible project information are vital for keeping everyone informed. A collaborative environment, where team members feel comfortable sharing ideas and concerns, fosters a stronger team dynamic and reduces conflicts. Utilizing project management software for communication and task management enhances efficiency and transparency.

Managing Risks and Challenges

Identifying potential risks and challenges early in the project is paramount. Risk assessments help anticipate potential problems like material shortages, labor disputes, or unforeseen code violations. Having contingency plans in place can mitigate these risks and minimize their impact on the project. For instance, securing backup material suppliers or having a contingency fund can help address delays.

Tracking Project Progress and Identifying Potential Delays

Project progress is best tracked using a system that allows for regular updates on task completion. A project schedule with milestones and deadlines facilitates this process. Regular progress reports, incorporating detailed time logs and task completion percentages, provide insight into potential delays. For instance, if a specific task is taking longer than anticipated, the team can proactively address the issue and adjust the schedule to mitigate the delay’s effect on other tasks. Monitoring key metrics, such as the percentage of tasks completed versus the planned schedule, helps identify and address potential delays early on.

Role of Quality Control in Electrical Projects

Quality control ensures that electrical installations meet industry standards and safety regulations. This involves rigorous inspections at various stages of the project, from material verification to final testing. Adherence to safety protocols and electrical codes is critical. Maintaining detailed records of inspections and tests is crucial for documentation and future reference. Employing qualified electricians and adhering to established quality control procedures are essential for producing high-quality work. This proactive approach prevents costly repairs and ensures customer satisfaction.

Compliance and Regulations

Source: edu.in

Following electrical codes and regulations is critical for safety, legal compliance, and project success. Ignoring these rules can lead to costly mistakes, safety hazards, and even legal repercussions. This section will cover the importance of compliance, various relevant codes, safety measures, consequences of non-compliance, and resources for understanding the regulations.

Significance of Adhering to Electrical Codes

Electrical codes and regulations are established to protect people and property from electrical hazards. They detail safe practices for the design, installation, and maintenance of electrical systems. Adherence to these codes minimizes the risk of fires, electrocution, and other serious accidents. Proper compliance also ensures the safety of the building occupants and workers during the installation process.

Different Electrical Codes and Standards

Various electrical codes and standards exist, each with specific requirements. National Electrical Code (NEC) is a widely recognized and important standard. Other codes may apply based on the project’s location, specific building type, or jurisdiction. For example, local municipalities may have their own supplemental codes.

Methods for Ensuring Compliance with Safety Regulations

Thorough review of all applicable codes and regulations is essential. Employing qualified and experienced electricians is a key aspect of project safety. Regular safety training sessions for all personnel involved in the project will also enhance safety. A well-documented safety plan that Artikels procedures, PPE requirements, and emergency protocols should be established and followed. A comprehensive checklist that covers every step of the project, from design to final inspection, is also vital.

Consequences of Non-Compliance with Electrical Codes, Electrical estimation and contracting

Non-compliance with electrical codes can have significant repercussions. Penalties may include fines, project delays, and even legal action. Furthermore, non-compliance can lead to hazardous conditions that pose significant risks to the health and safety of individuals and the surrounding community. The project may also face rejection or suspension. There is also the risk of injury or death to workers and building occupants due to faulty or improperly installed electrical systems.

Resources for Accessing and Understanding Relevant Electrical Codes and Regulations

Several resources are available to help understand and apply electrical codes. The National Fire Protection Association (NFPA) website is a valuable resource for the NEC and other relevant codes. Local building departments and electrical inspectors can also provide guidance. Furthermore, experienced electrical consultants and engineers can offer expertise on complex code applications.

Process of Obtaining Necessary Permits and Approvals

The process of obtaining permits and approvals involves several steps. These typically include submitting required documentation, scheduling inspections, and adhering to timelines. Contacting the local building department or relevant authority is the first step. Ensuring that all necessary permits are obtained and approvals are received before any work begins is crucial for avoiding significant project delays. The process should be followed closely to avoid penalties or delays in the project.

Contractual Aspects

Contracts are the bedrock of any electrical contracting project. A well-drafted contract clearly Artikels the responsibilities, expectations, and potential liabilities of all parties involved. This ensures smooth project execution and minimizes disputes. Without a robust contract, projects can easily get derailed by misunderstandings and disagreements.

A comprehensive contract serves as a roadmap, defining everything from payment terms to project completion deadlines. It acts as a legal agreement, safeguarding the interests of all parties involved. A clear contract fosters trust and cooperation, making the project more likely to succeed on time and within budget.

Importance of Clear and Comprehensive Contracts

A well-structured electrical contract minimizes the risk of disputes and misunderstandings throughout the project lifecycle. It provides a clear framework for communication, ensuring that all parties understand their obligations and rights. This transparency significantly reduces the chance of costly delays and rework. A well-defined contract also protects against unforeseen circumstances, offering a structured path for addressing potential issues.

Key Elements of a Well-Structured Electrical Contract

A strong electrical contract encompasses several crucial elements. These include project scope, payment schedule, timelines, and termination clauses. It’s essential to clearly define the work to be performed, including materials, labor, and timelines. Precise specifications help avoid ambiguities and ensure that the final product meets the client’s requirements.

- Project Scope: A detailed description of the work to be performed, including all tasks, materials, and deliverables. This prevents misunderstandings about the extent of the project.

- Payment Schedule: Clearly Artikels the payment terms, milestones, and penalties for late payments. This element promotes transparency and avoids potential payment disputes.

- Timelines: Defines the project’s start and completion dates, key milestones, and penalties for delays. This is crucial for managing expectations and preventing project overruns.

- Termination Clauses: Specifies the conditions under which either party can terminate the contract, including the associated procedures and liabilities. This protects against unforeseen circumstances.

Different Types of Contractual Arrangements

Different contractual arrangements suit various project needs. Understanding these options is vital for choosing the most appropriate approach.

- Fixed-Price Contracts: The contractor agrees to a set price for the entire project, regardless of the actual costs incurred. This approach is suitable when the project scope is well-defined and predictable.

- Cost-Plus Contracts: The contractor is reimbursed for all project costs, plus a predetermined markup. This approach is often used when the project scope is uncertain or subject to change.

- Time and Materials Contracts: The contractor is paid for the time spent and the materials used. This approach is beneficial when the project’s scope is not entirely fixed.

Resolving Disputes and Conflicts

Disputes can arise in any project. A well-structured contract should include provisions for resolving disputes.

- Dispute Resolution Mechanisms: Agreements outlining methods for resolving conflicts, such as mediation or arbitration. This can save time and money compared to litigation.

- Mediation: A neutral third party helps facilitate communication and negotiation between the parties to reach a mutually agreeable solution.

- Arbitration: A neutral third party makes a binding decision on the dispute. This can be faster and less expensive than court proceedings.

Legal Implications of Different Contractual Clauses

Different contractual clauses have distinct legal implications.

- Warranty Clauses: Guarantees for the quality and performance of the work, specifying remedies for defects or failures. These clauses protect the client and establish the contractor’s responsibility for the work.

- Indemnification Clauses: Shifting the responsibility for certain risks to a party. These clauses are crucial for protecting the parties involved from unforeseen liabilities.

Significance of Indemnification Clauses

Indemnification clauses transfer liability for certain risks to a party. They protect the parties involved from potential harm. A well-crafted indemnification clause clearly defines the scope of the risk transfer and the circumstances under which it applies.

Last Point

Source: electricalestimation.us

In conclusion, electrical estimation and contracting requires a meticulous approach, combining technical expertise with strong project management skills. This guide has equipped you with the knowledge to navigate the complexities of electrical projects, from accurate estimations to successful project completion. Remember, compliance with regulations and clear communication are key to a smooth and profitable outcome.