Electrical Estimation and Contracting A Comprehensive Guide

Electrical estimation and contracting a crucial aspects of the construction industry. It involves precisely calculating the materials and labor needed for any electrical project, from small residential jobs to large commercial installations. Understanding the intricacies of this field is vital for successful project completion, avoiding costly mistakes, and building strong client relationships. This guide dives deep into the essential elements, from estimation procedures to project management, safety considerations, and contract specifics. We’ll cover everything from common project types to the tools and techniques used in the industry.

The process of electrical estimation and contracting requires a detailed understanding of various factors. From calculating material quantities and labor costs to managing project timelines and budgets, every aspect of this field is crucial for success. This guide will equip you with the knowledge and tools needed to navigate the complexities of electrical projects, ensuring accuracy, efficiency, and profitability.

Introduction to Electrical Estimation and Contracting

Electrical estimation and contracting involve the meticulous planning, pricing, and execution of electrical work in various projects. From residential houses to complex commercial buildings, electrical professionals ensure safe, efficient, and reliable electrical systems. This process requires a deep understanding of electrical codes, materials, labor costs, and project timelines. Accurate estimations are crucial for profitable projects and client satisfaction.

Electrical contracting encompasses a broad range of tasks, from designing and installing wiring systems to overseeing the installation of complex electrical equipment. The process is highly technical, demanding attention to detail and adherence to strict safety protocols. Contractors need to manage project budgets, schedules, and personnel effectively to deliver projects on time and within budget.

Scope of Work in Electrical Projects

Electrical projects often involve a range of tasks, including designing and installing wiring systems, setting up lighting fixtures, installing electrical outlets and switches, installing electrical panels and subpanels, running conduits, and connecting electrical equipment. These tasks require careful planning and execution to meet safety standards and comply with local electrical codes. Projects may also involve the installation of specialized equipment, such as security systems, fire alarm systems, or renewable energy systems.

Common Project Types in Electrical Contracting

Residential electrical work encompasses projects like installing new wiring, replacing outdated systems, and adding outlets and lighting in houses. Commercial projects often involve more complex systems, such as installing electrical systems in offices, retail spaces, or industrial facilities. Industrial electrical projects may focus on large-scale systems, heavy machinery, and specialized equipment installations. Other common project types include renovations, additions, and upgrades to existing electrical systems.

Importance of Accurate Estimations

Accurate estimations are vital for the success of electrical contracting projects. Underestimating costs can lead to project losses while overestimating can deter potential clients. Precise estimations consider all aspects of the project, including material costs, labor costs, permits, and potential delays. Accurate estimations contribute to project profitability and client satisfaction. A well-defined estimate minimizes the chance of disputes and ensures a successful outcome for both the contractor and the client.

Key Skills for Electrical Estimators and Contractors

Successful electrical estimators and contractors require a blend of technical and soft skills. Technical skills include a strong understanding of electrical codes, materials, and equipment. Estimators need proficiency in using estimation software and databases. Contractors must possess hands-on expertise in electrical installation and maintenance. Soft skills are equally important, encompassing excellent communication, problem-solving, and leadership abilities. Building strong relationships with clients and subcontractors is crucial for successful project management.

- Technical Skills: A solid understanding of electrical codes, materials, and equipment is essential. Knowledge of estimation software and databases is crucial for accurate and efficient estimations. Hands-on expertise in electrical installation and maintenance is also vital for contractors.

- Soft Skills: Excellent communication, problem-solving, and leadership skills are essential for managing projects and interacting with clients and subcontractors. The ability to build strong relationships is crucial for successful project outcomes.

Typical Costs of Electrical Projects

Estimating the precise cost of electrical projects depends on several factors. Project size, complexity, and location influence the overall cost. Materials, labor, and permit fees are significant cost components. Here’s a table showcasing some common electrical project types and their estimated cost ranges:

| Project Type | Estimated Cost Range (USD) |

|---|---|

| Residential Wiring Upgrade | $1,500 – $10,000 |

| Commercial Office Electrical Installation | $20,000 – $100,000+ |

| Industrial Machinery Wiring | $50,000 – $500,000+ |

| Solar Panel Installation (Residential) | $5,000 – $20,000 |

These cost ranges are estimates and can vary considerably based on specific project requirements, local labor rates, and material costs. Always consult with a qualified electrical contractor for a precise quote.

Estimating Procedures and Methods

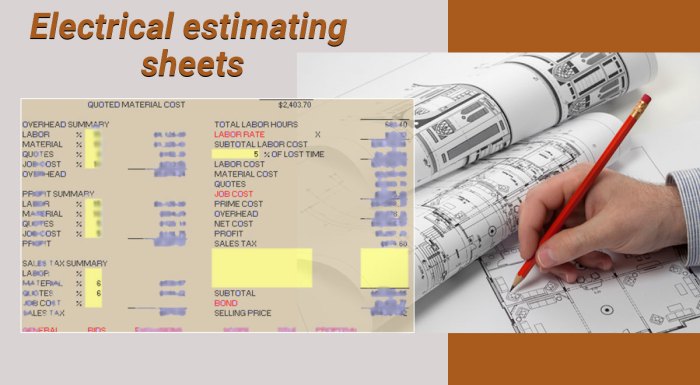

Source: qtoconstruction.com

Figuring out the total cost of an electrical project accurately is crucial for success. A precise estimate ensures you’re not underbidding and losing money, or overbidding and scaring off potential clients. This involves more than just adding up materials; it’s a systematic process of understanding all the project elements and their associated costs.

Accurate estimations rely on a well-defined methodology. This involves careful planning, data collection, and a keen understanding of both material and labor costs. By following established procedures, contractors can avoid costly mistakes and ensure profitable projects.

Calculating Material Quantities

Precise material quantity calculations are fundamental to a sound electrical estimate. Different methods exist, each tailored to specific project types and complexities. For instance, detailed drawings are essential for complex projects, allowing precise measurements of conduit, wire, and other materials. Simple projects, however, may rely on estimations based on established industry norms.

- Takeoff from Drawings: For complex projects, detailed drawings provide the most accurate data for calculating material quantities. This method involves meticulously measuring wire runs, conduit lengths, and the quantities of other components.

- Unit Rate Method: This approach is useful for repetitive tasks. By determining the cost per unit (e.g., per foot of wire), you can estimate the total cost for the project.

- Historical Data: Contractors often use previous project data to estimate material quantities for similar jobs. This method is faster but requires careful consideration of differences between the projects.

Creating an Accurate Electrical Estimate

A thorough estimate considers all project aspects, including materials, labor, and potential contingencies. The process follows a logical sequence to ensure accuracy and comprehensiveness.

- Project Review: Carefully examining the project specifications, drawings, and any additional information provided is the first step. This ensures a clear understanding of the scope of work.

- Material Quantity Calculation: The steps described above are crucial for determining precise material requirements.

- Labor Cost Estimation: A significant component of any electrical project cost. Consider the required labor hours for each task, along with labor rates for different skill levels.

- Contingency Planning: Unexpected issues can arise during any project. Allocating a contingency budget for unforeseen circumstances is vital.

- Cost Summarization: This involves compiling all the costs (materials, labor, and contingency) into a comprehensive summary, presenting a clear picture of the total estimated project cost.

Considering Labor Costs

Labor costs are a critical factor in electrical estimations. They significantly impact the project’s profitability. Accurately estimating labor hours and considering the skill levels of the workforce are essential.

Labor costs are frequently a larger portion of the total project cost than material costs.

Accurately estimating labor hours and considering the skill levels of the workforce are essential. Factors like labor rates, overtime pay, and any additional project-specific costs must be included.

Common Mistakes and Avoidance Strategies

Several mistakes can negatively affect electrical estimations. Recognizing these errors and implementing preventative measures is vital.

- Inadequate Planning: Failure to thoroughly review project specifications and drawings can lead to inaccurate estimations.

- Ignoring Labor Costs: Underestimating labor hours or neglecting the skill level required can drastically affect the final project cost.

- Neglecting Contingencies: Failure to allocate a contingency budget can lead to cost overruns and project delays.

Using Industry Standards and Codes

Adherence to industry standards and codes is paramount in electrical estimations. Understanding these regulations ensures compliance and helps avoid costly penalties.

- NEC (National Electrical Code): The NEC provides crucial guidelines for electrical installations, which must be followed during estimations.

- Local Codes: Local codes often contain additional regulations specific to a given area.

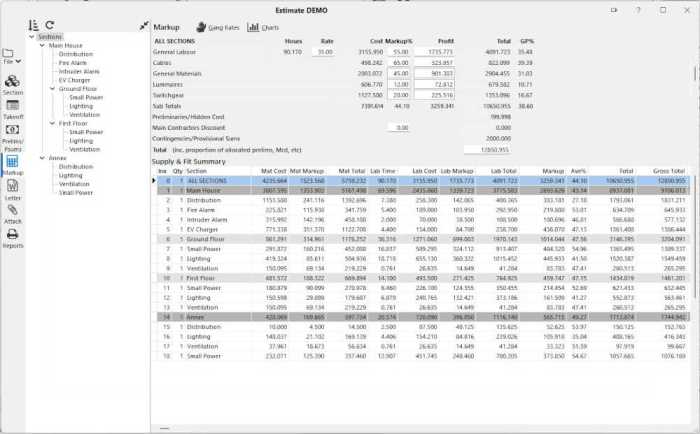

Electrical Estimation Software Comparison

The right software can streamline the estimation process. Different software packages offer varying levels of functionality and features.

| Software | Features | Pros | Cons |

|---|---|---|---|

| Software A | Detailed material takeoff, labor cost tracking, reporting | Comprehensive, accurate | Steeper learning curve |

| Software B | Simple material takeoff, basic reporting | Easy to use, affordable | Limited functionality |

| Software C | Cloud-based, collaboration features | Teamwork, accessibility | Potential for limited customization |

Materials and Equipment: Electrical Estimation And Contracting

Choosing the right electrical materials and equipment is crucial for a successful and safe electrical contracting project. It directly impacts the project’s cost, efficiency, and overall quality. Selecting the wrong materials can lead to costly rework, safety hazards, and delays. This section dives into the critical aspects of material and equipment selection for electrical contractors.

Common Electrical Materials and Equipment

Electrical contracting utilizes a wide array of materials and equipment, ranging from basic wiring to complex control panels. Common materials include various types of conductors (wires and cables), insulators, connectors, and switches. Equipment can span from basic hand tools to sophisticated testing devices and protective gear. The specific materials and equipment needed depend heavily on the project’s scope and complexity.

Importance of Selecting Appropriate Materials and Equipment

Selecting appropriate materials and equipment is paramount. Using substandard materials can compromise the project’s safety, reliability, and longevity. This might manifest as overheating, short circuits, or even fires. Conversely, using high-quality materials ensures the installation meets safety codes, operates efficiently, and lasts for many years.

Factors to Consider When Choosing Electrical Materials

Several key factors influence the selection of electrical materials. These include the project’s voltage requirements, the amperage needed to support the load, the type of environment the installation will be in (e.g., damp, dry, or hazardous locations), and the necessary safety features. Additionally, the specific standards and regulations enforced in the area must be adhered to. Consideration of future upgrades and potential expansion is also a valuable aspect.

Safety in Selecting Materials and Equipment

Safety should be a top priority when choosing electrical materials and equipment. Materials must meet industry safety standards and comply with relevant regulations. Electrical contractors must prioritize materials that minimize risks and provide sufficient protection. This includes using appropriate insulation, ensuring proper grounding, and selecting tools with safety features. Using materials certified for their intended use is critical to ensure the safety of workers and the public.

Different Pricing Models for Electrical Materials

Electrical materials are often priced based on the material’s specifications and the quantity required. Different pricing models may include per-unit pricing, bulk discounts, or contracts. Contractors should carefully evaluate pricing models to identify the most cost-effective options. A clear understanding of the pricing structure is essential for accurate cost estimations and budgeting.

Electrical Wiring Types and Applications

The table below provides a concise overview of common electrical wiring types and their typical applications. Different wiring types are designed for specific environments and loads, and using the right type is essential for safety and performance.

| Wiring Type | Description | Typical Applications |

|---|---|---|

| NM-B (Romex) | Non-metallic sheathed cable | Residential wiring, light fixtures, and simple commercial installations. |

| UF-B (Underground Feeder) | Underground Feeder cable | Underground installations, buried runs for outdoor applications. |

| THHN/THWN | Thermoplastic-insulated wire | GeGeneral-purposeiring in both residential and commercial projects, including concealed runs and exposed installations. |

| MC Cable | Metal-clad cable | Industrial and commercial installations, where the cable needs mechanical protection and high amperage requirements. |

Project Management in Electrical Contracting

Project management is crucial for electrical contracting firms to deliver projects on time and within budget. Effective project management ensures smooth coordination between various teams, resources, and tasks, minimizing delays and cost overruns. This, in turn, boosts client satisfaction and maintains the firm’s reputation for reliability.

The Role of Project Management

Project management in electrical contracting involves planning, organizing, directing, and controlling all project activities. This includes defining project scope, setting timelines, allocating resources, managing budgets, and ensuring quality control. Effective project managers act as the central point of communication, ensuring all stakeholders (clients, subcontractors, and internal teams) are aligned and informed about progress.

Stages of a Typical Electrical Project

Electrical projects typically follow a structured sequence of stages. These stages ensure the project is completed systematically and efficiently, minimizing errors and rework.

- Project Initiation: This initial phase involves defining the project’s objectives, scope, and deliverables. Key activities include client meetings, contract negotiation, and developing a preliminary project plan.

- Planning: Detailed planning occurs in this stage, encompassing resource allocation, scheduling, and budget development. This phase involves creating a comprehensive project schedule and identifying potential risks and mitigation strategies.

- Execution: This stage encompasses the actual construction work. Close monitoring and control are essential to ensure the project stays on schedule and within budget.

- Monitoring and Controlling: Regular progress monitoring, quality control checks, and budget tracking are critical during this stage. This helps identify and address deviations from the plan promptly.

- Project Closure: The final stage involves project completion, final inspections, client acceptance, and administrative tasks like project documentation and record keeping. It’s crucial to complete all necessary paperwork and ensure the project is officially closed.

Importance of Communication in Electrical Projects

Effective communication is paramount in electrical projects. Clear and consistent communication ensures all stakeholders understand their roles, responsibilities, and project updates. This minimizes misunderstandings, reduces errors, and fosters a collaborative environment.

- Regular meetings: Frequent communication through meetings, email, and project management software is vital. This ensures everyone is on the same page regarding project status and any potential issues.

- Clear documentation: Comprehensive documentation of all project details, decisions, and communication is crucial. This provides a clear record of the project and assists in future projects.

- Feedback mechanisms: Establishing feedback mechanisms enables stakeholders to provide input and address concerns promptly. This fosters a more collaborative and problem-solving environment.

Managing Project Timelines and Budgets

Accurate project timelines and budgets are essential for successful electrical projects. Project managers need to develop realistic schedules and budgets, considering all potential factors.

- Realistic scheduling: Project timelines should be realistic, considering potential delays and resource constraints. Using project management software can assist in creating accurate schedules.

- Budget control: Budget management involves tracking expenses and identifying any deviations. This enables timely adjustments and prevents cost overruns.

- Contingency planning: A contingency plan addresses potential issues or risks that could impact the timeline or budget. This proactive approach helps minimize project disruptions.

Identifying Potential Risks and Challenges

Electrical projects face various risks and challenges. Recognizing and mitigating these potential issues is essential for successful project completion.

- Code compliance: Adherence to local electrical codes and regulations is crucial. Non-compliance can lead to significant delays and penalties.

- Material availability: Unforeseen material shortages can delay projects. Project managers should establish contingency plans for material sourcing.

- Weather conditions: Extreme weather can affect construction timelines and impact the safety of workers.

Project Management Software Options

Different project management software solutions cater to various needs and budgets. Choosing the right software can significantly streamline project management.

| Software | Description | Pros | Cons |

|---|---|---|---|

| Asana | A task management tool | User-friendly interface, collaborative features | Limited reporting capabilities |

| Trello | A visual project management tool | Intuitive interface, flexible workflows | Not ideal for complex projects |

| Monday.com | A customizable platform | Highly adaptable to various project types | Steeper learning curve |

| Microsoft Project | A comprehensive project management software | Robust features, a wide range of tools | Can be an expensive, complex interface |

Safety and Compliance in Electrical Contracting

Electrical contracting involves high-voltage equipment and potentially hazardous situations. Prioritizing safety is paramount, not just a best practice, but a fundamental requirement. This section delves into the crucial aspects of safety regulations, best practices, and legal compliance within the electrical contracting industry.

Importance of Safety Regulations

Safety regulations in electrical work are not optional; they’re essential for protecting workers, preventing accidents, and safeguarding public safety. These regulations Articulate the minimum standards for electrical installations and procedures, aiming to minimize risks and ensure compliance with legal requirements. Adhering to these standards is critical for preventing electrical shocks, fires, and other serious incidents.

Best Practices for Maintaining a Safe Work Environment

Establishing a safe work environment is a continuous process. It involves implementing proactive measures to prevent accidents, rather than just reacting to them. Key practices include regular safety inspections of equipment, proper training for all personnel, and clear communication protocols for potential hazards. Proper signage and barricading are essential to alert personnel and the public to dangerous areas.

Key Safety Equipment Required for Electrical Projects

Safety equipment is vital for protecting workers during electrical projects. This includes insulated tools, gloves, safety glasses, and appropriate personal protective equipment (PPE) like high-voltage test equipment, grounding devices, and arc flash gear. Proper selection and use of this equipment are crucial for preventing injuries and ensuring the safety of personnel. For example, using insulated tools when working with live wires significantly reduces the risk of electric shock.

Legal and Regulatory Requirements for Electrical Contractors, Electrical estimation and contracting

Electrical contractors must adhere to local, state, and federal regulations. These regulations cover permits, licensing, and specific safety standards. Non-compliance can lead to significant penalties and legal repercussions. Understanding and adhering to these regulations is critical for maintaining a lawful and safe operation. Examples of such regulations include OSHA standards and local building codes.

Importance of Obtaining Necessary Permits and Licenses

Obtaining the necessary permits and licenses is a legal obligation for electrical contractors. Permits ensure that work is done according to established codes and regulations, while licenses validate the contractor’s qualifications and expertise. Failure to obtain required permits and licenses can result in project delays, legal action, and potential financial penalties. Always verify the necessary permits and licenses required for the specific project and jurisdiction.

Common Safety Hazards and Prevention Methods

| Safety Hazard | Prevention Method |

|---|---|

| Electric Shock | Using insulated tools, proper grounding procedures, lockout/tagout procedures, and regular equipment inspections. |

| Arc Flash | Wearing appropriate arc flash gear, using lockout/tagout procedures, and maintaining equipment in good condition. Proper training on arc flash hazards is essential. |

| Falls | Using appropriate fall protection equipment, securing work areas, and ensuring proper scaffolding and ladder use. |

| Electrocution | Ensuring proper insulation and grounding of electrical equipment. Always verify power is off before working on live wires. |

| Fires | Maintaining proper ventilation, using appropriate fire safety equipment, and adhering to fire prevention procedures. Regularly checking electrical wiring for overheating is vital. |

This table highlights common hazards and the corresponding preventive measures. Consistent implementation of these methods is crucial for a safe work environment.

Cost Analysis and Budgeting

Source: exactdn.com

Figuring out the financial side of an electrical project is crucial. It’s not just about adding up materials; it’s about anticipating potential problems and making sure you’re charging a fair price that covers your work and materials. A solid cost analysis and budget are your roadmap to project success.

Understanding your project’s costs allows for effective planning and resource allocation. Accurate cost estimates are the foundation for a profitable project and client satisfaction. Properly forecasting costs, including contingency planning, can significantly reduce risks and increase the likelihood of a successful project.

Project Cost Analysis Framework

A comprehensive cost analysis framework should cover all aspects of the project, from materials and labor to permits and overheads. A clear breakdown helps avoid cost overruns and allows for proactive adjustments.

Components of Project Costs

Electrical projects have many cost components. These are typically categorized as:

- Direct Costs: These are directly tied to the project. Examples include materials (wires, conduits, panels), labor costs (electricians, apprentices), and equipment rentals.

- Indirect Costs: These are costs that support the project, like administrative expenses, permits, and insurance. They aren’t directly related to the work itself but are still vital.

- Contingency Costs: These are allowances for unexpected expenses or unforeseen circumstances. They’re essential for maintaining project profitability and are a critical component of the budget.

Methods for Forecasting Future Costs

Accurate cost forecasting is essential. Methods include:

- Historical Data Analysis: Reviewing past project costs provides valuable insights into material and labor expenses. Analyzing historical data helps you make informed predictions for current projects.

- Market Research: Keeping up with material price fluctuations and labor market rates helps adjust estimates for current projects.

- Expert Opinions: Consulting with experienced electricians and estimators can provide valuable insights into potential challenges and cost adjustments.

Importance of Contingency Planning

Contingency planning is crucial for electrical projects. Unforeseen circumstances, such as material shortages, permit delays, or unexpected design changes, can significantly impact the project timeline and budget. A well-defined contingency plan helps mitigate these risks.

Creating a Detailed Project Budget

Creating a detailed project budget involves several steps:

- Detailed Cost Breakdown: Carefully list all anticipated expenses, separating direct, indirect, and contingency costs.

- Time-Phased Budget: Allocate costs to specific project phases (e.g., design, procurement, installation). This allows for better monitoring and control throughout the project lifecycle.

- Approval and Review: Share the budget with relevant stakeholders for approval and feedback. This ensures all parties are on the same page regarding the project’s financial plan.

Typical Cost Breakdown for a Medium-Sized Electrical Project

A medium-sized electrical project (e.g., 1,000-2,000 square feet residential addition) might have these typical cost breakdowns. These are estimations and can vary widely based on the specifics of the project.

| Category | Estimated Percentage |

|---|---|

| Materials | 30-40% |

| Labor | 40-50% |

| Permits and Inspections | 5-10% |

| Contingency | 5-10% |

| Overhead | 5-10% |

Contracts and Agreements

Source: co.uk

Contracts are the bedrock of any electrical contracting project. A well-drafted contract Articulates the responsibilities, expectations, and payment terms for both the contractor and the client. This prevents misunderstandings and potential disputes down the line, ensuring a smooth and profitable project execution. Without a robust contract, the project is vulnerable to ambiguity and potential financial losses.

A solid contract serves as a legally binding agreement that protects both parties involved. It defines the scope of work, payment schedules, timelines, and other crucial details. It acts as a safety net, safeguarding the interests of all parties involved in the project. A contract, in essence, acts as a roadmap, guiding the project from start to finish.

Importance of Well-Defined Contracts

Clear contracts in electrical work are crucial for several reasons. They establish mutual understanding, Artikel specific responsibilities, and protect both the contractor and client from unforeseen circumstances. This transparency minimizes the likelihood of disputes and helps ensure a positive working relationship. Contracts also act as a reference point for resolving any ambiguities during the project lifecycle.

Key Elements of a Standard Electrical Contract

A comprehensive electrical contract typically includes:

- Project description: A detailed description of the electrical work to be performed, including specific tasks, materials, and equipment.

- Scope of work: A clear and concise definition of the project’s boundaries, including what’s included and excluded from the contract.

- Payment terms: A detailed article on payment schedules, milestones, and methods of payment. This often includes deposit amounts, progress payments, and final payment terms.

- Timeline: A schedule outlining the project’s start and completion dates, including key milestones.

- Warranties: Details on any warranties provided by the contractor regarding the workmanship and materials used.

- Dispute resolution mechanisms: A clear procedure for resolving any disagreements or disputes that may arise during the project.

Different Types of Contract Clauses and Their Implications

Various clauses in a contract govern different aspects of the project. Some common clauses include:

- Payment clauses: These dictate the payment schedule, method, and penalties for late payments. A clear payment schedule is crucial to ensure the contractor is paid fairly and on time.

- Change order clauses: These Artikel the procedure for handling changes to the original scope of work. A well-defined change order process avoids misunderstandings and ensures both parties are compensated appropriately for any additions or alterations.

- Termination clauses: These specify the conditions under which either party can terminate the contract. Clearly defining these circumstances helps to mitigate risks and protect both parties.

- Indemnification clauses: These clauses detail how one party will compensate the other for damages resulting from the project. Such clauses are critical to protect against unforeseen liabilities.

Handling Disputes and Disagreements

Disputes are an unfortunate but inevitable aspect of any large project. A well-structured contract should include a clear dispute resolution process, potentially involving arbitration or mediation. This process aims to resolve disagreements amicably and efficiently.

“Proactive dispute resolution is far more cost-effective than protracted litigation.”

Examples of Clauses to Include in Electrical Contracts

Examples of clauses that can be included in electrical contracts:

- Materials clause: Describing the materials to be used, including their specifications and quality.

- Inspection and testing clause: Outlining the procedures for inspecting and testing the completed electrical work.

- Insurance clauses: Detailing the insurance coverage required for the project.

Types of Contracts and Legal Considerations

Different types of contracts have varying legal implications.

| Contract Type | Legal Considerations |

|---|---|

| Fixed-price contract | Agreement for a set price regardless of time or effort; risk of cost overruns if unexpected issues arise. |

| Time and materials contract | Agreement for payment based on time spent and materials used; useful for projects with uncertain scope. |

| Unit price contract | Agreement for payment based on the quantity of work performed; suitable for projects with readily quantifiable work. |

Customer Relations and Communication

Keeping clients happy is key to any successful electrical contracting business. Positive client relationships lead to repeat business, referrals, and a strong reputation. Excellent communication is the cornerstone of these relationships, ensuring clear expectations, smooth project execution, and ultimately, a satisfied customer.

Importance of Effective Communication

Effective communication with clients is vital for project success. It builds trust, minimizes misunderstandings, and allows for proactive problem-solving. Open communication channels facilitate the sharing of crucial information, ensuring everyone is on the same page regarding project timelines, budgets, and potential challenges.

Best Practices for Handling Client Inquiries and Feedback

Responding promptly and professionally to client inquiries and feedback is crucial. This involves actively listening to their concerns, addressing them thoroughly, and following up with clear and concise updates. Maintain a professional and courteous tone, even when dealing with challenging situations. Use written communication (emails, project updates) whenever possible to maintain a record of discussions and agreed-upon actions. This approach helps avoid misinterpretations and fosters transparency.

Building Strong Relationships with Clients

Building strong relationships with clients involves more than just completing the project on time and within budget. It involves proactive communication, anticipating needs, and going the extra mile to exceed expectations. Regular check-ins, proactive updates, and addressing concerns before they escalate are essential elements of fostering a positive relationship. Understanding client needs and tailoring communication styles accordingly enhances rapport and trust.

Methods for Resolving Customer Complaints

Addressing customer complaints promptly and effectively is essential for maintaining a positive reputation. Listen actively to the complaint, acknowledge the client’s concerns, and empathize with their frustration. Offer solutions that address the root cause of the problem and commit to a resolution plan. Document the entire process, including the complaint, the steps taken to resolve it, and the outcome. This documentation serves as a valuable learning tool for future projects and demonstrates a commitment to customer satisfaction.

Role of Customer Service in Project Success

Customer service is integral to the success of electrical projects. It influences project completion time, budget adherence, and ultimately, client satisfaction. Effective customer service ensures clear expectations, minimizes misunderstandings, and facilitates a smooth project execution. It builds trust and rapport, making clients more receptive to advice and suggestions. Proactive communication, problem-solving, and a focus on exceeding expectations are crucial for a successful customer service strategy.

Different Methods for Communicating with Clients

| Communication Method | Advantages | Disadvantages |

|---|---|---|

| Phone Calls | Immediate feedback, personal connection, clarification of complex issues | Can be time-consuming, difficult to document, and may not be suitable for all situations |

| Emails | A formal record of communication, easy to distribute updates, accessible to multiple parties | Can be impersonal, difficult to convey tone and emotion, and may not be suitable for urgent issues. |

| Project Management Software | Centralized communication hub, clear visibility of project progress, automated updates | Requires initial setup, may not be accessible to all clients, the potential for technical issues |

| In-person Meetings | Face-to-face interaction, builds rapport, and opportunities for in-depth discussions. | Can be time-consuming, logistically challenging, and may not be feasible for all clients. |

| Text Messages | Quick communication, useful for updates and reminders | Less formal, not suitable for detailed discussions, potentially difficult to maintain a professional tone |

Epilogue

Source: candelsoncall.com

In summary, electrical estimation and contracting is a multifaceted field that demands careful planning, accurate calculations, and a strong understanding of safety regulations. By meticulously following the procedures and guidelines Artikel in this guide, you can ensure smooth project execution, maintain client satisfaction, and achieve profitability. This guide provides a comprehensive overview of the essential elements for navigating the electrical contracting landscape, from estimation to project management and client relations. Remember, precision and safety are paramount in this industry.